Building Cabinet Doors with a Kreg Jig: Cabinet Doors Kreg Jig

Constructing high-quality cabinet doors with a Kreg Jig offers a blend of speed and precision, particularly appealing to those seeking a balance between DIY affordability and professional results. However, the method is not without its limitations, and careful consideration of material selection, joinery techniques, and design choices is crucial for achieving a durable and aesthetically pleasing outcome. Ignoring these factors can lead to weak joints and ultimately, a subpar product.

Material Selection for Cabinet Doors

The choice of wood significantly impacts the final product’s durability, aesthetics, and cost. Hardwoods generally offer superior strength and visual appeal, but come at a higher price point. Softwoods provide a more budget-friendly option, but may require more careful handling during construction to avoid damage.

| Wood Type | Pros | Cons | Cost |

|---|---|---|---|

| Maple | Hard, durable, smooth finish | Can be expensive, prone to chipping | High |

| Cherry | Beautiful grain, rich color | Can be soft, susceptible to dents | High |

| Pine | Affordable, easy to work with | Soft, prone to dents and scratches | Low |

| Birch | Strong, relatively inexpensive, consistent grain | Can be less visually striking than some hardwoods | Medium |

Pocket Hole Joinery: Advantages and Disadvantages

Pocket hole joinery, facilitated by a Kreg Jig, offers a relatively quick and strong method for assembling cabinet doors. The hidden nature of the joinery contributes to a clean aesthetic. However, the strength of the joint is dependent on proper technique and screw selection. Over-tightening can lead to splitting, while under-tightening results in weak joints. Compared to dowels or biscuits, pocket holes offer a greater degree of forgiveness for minor inaccuracies in alignment, but may not achieve the same level of seamlessness. Dowels provide a very strong joint, but require precise drilling, while biscuits are less strong but faster to assemble.

Optimal Pocket Hole Placement for Cabinet Doors

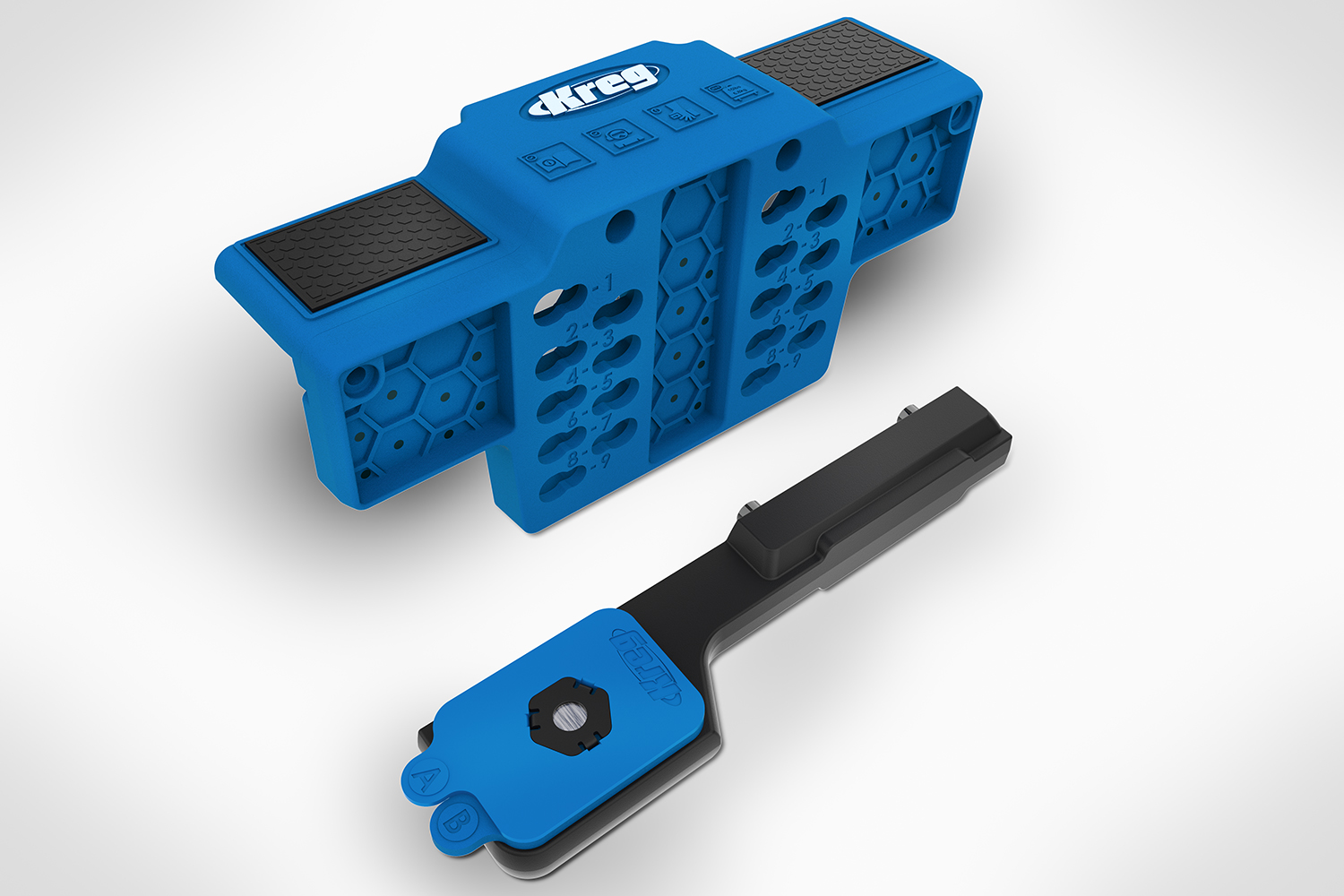

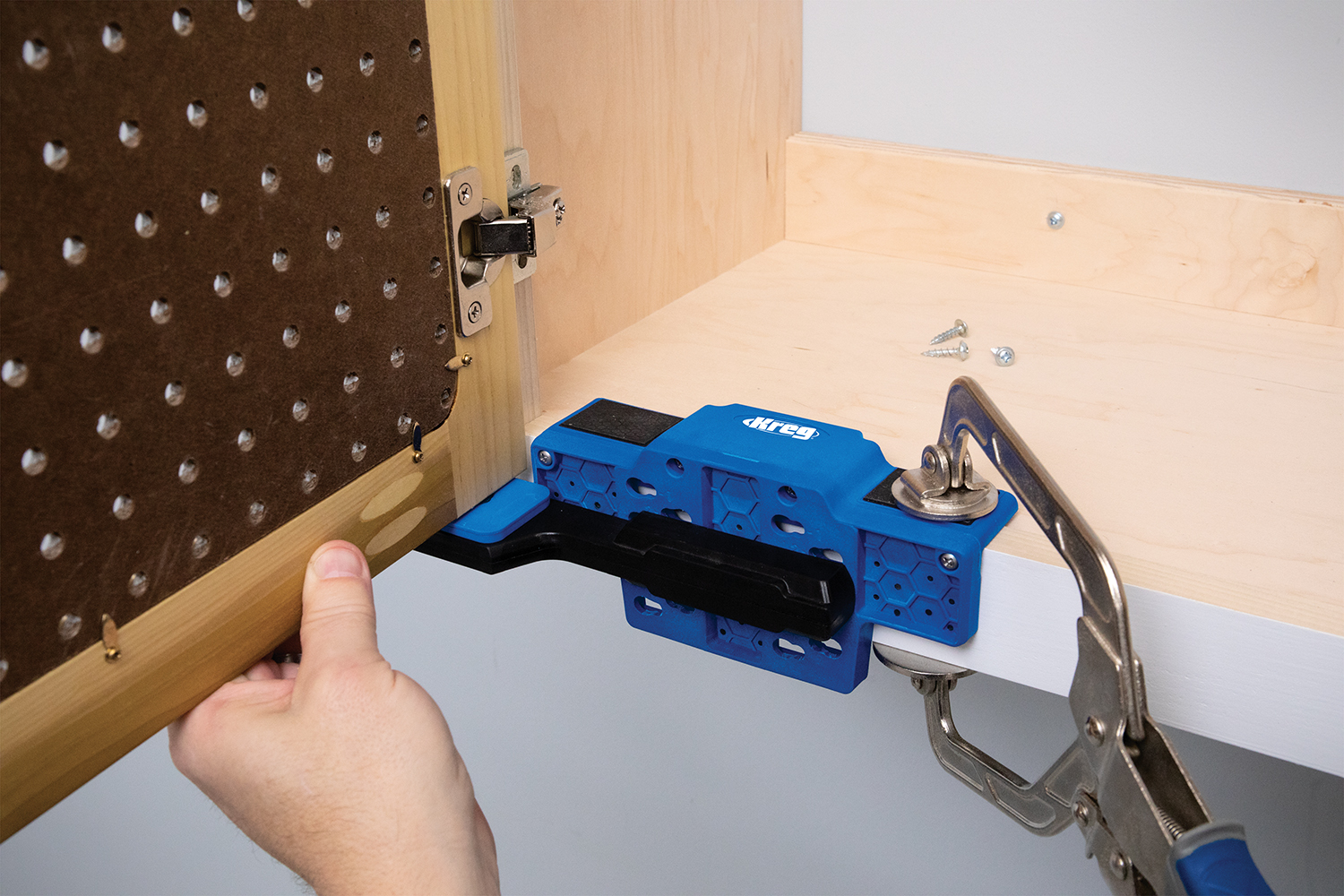

The illustration depicts a cabinet door with pocket holes strategically placed along the inside edges of the frame, near the stiles and rails. The holes are angled to ensure the screws pull the pieces together firmly, creating a strong joint. The pocket holes are countersunk to allow for a flush surface, minimizing their visual impact. Placement should avoid areas subject to high stress or visible from the front. The image shows a consistent spacing of the pocket holes to distribute the stress evenly across the joint. The screws used are specifically designed for pocket hole joinery and are long enough to provide sufficient grip without exceeding the depth of the door components.

Cabinet Door Styles

The design of a cabinet door should complement the overall kitchen aesthetic. Three distinct styles demonstrate the versatility of the Kreg Jig.

Cabinet doors kreg jig – Style 1: Shaker Style

- Wood Type: Maple

- Hardware: Simple, brushed nickel knobs

- Construction: A simple frame and panel design with clean lines and minimal ornamentation.

Style 2: Modern Slab Door

- Wood Type: Walnut

- Hardware: Sleek, minimalist bar handles

- Construction: A solid panel door with no frame, showcasing the wood grain.

Style 3: Traditional Raised Panel

- Wood Type: Cherry

- Hardware: Ornate, brass knobs

- Construction: A frame and raised panel design, with a decorative raised panel inset into the frame.

Troubleshooting and Optimizing Kreg Jig Use for Cabinet Doors

The seemingly simple act of crafting cabinet doors with a Kreg Jig often hides a minefield of potential pitfalls. Ignoring even minor details can lead to frustrating inaccuracies, weakened joints, and ultimately, a subpar final product. This section dissects common errors, compares Kreg Jig models, and provides strategies for achieving professional-level results.

Common Mistakes and Their Solutions, Cabinet doors kreg jig

Improper jig setup and execution are the most frequent culprits in Kreg Jig cabinet door construction failures. These errors, if left unaddressed, compromise both the structural integrity and the aesthetic appeal of the finished doors.

- Incorrect Clamp Pressure: Insufficient clamping pressure results in loose pocket holes and inaccurate screw placement. This leads to weak joints prone to failure. Solution: Always ensure firm, even clamping pressure across the workpiece before drilling. Use additional clamps if necessary for larger or awkwardly shaped pieces.

- Misaligned Wood: If the wood is not properly aligned within the jig, the pocket holes will be misaligned, creating an uneven joint. This can result in gaps and a visually unappealing finish. Solution: Double-check the alignment of the wood against the jig’s fence and stop blocks before drilling. Use a square to ensure perfect alignment.

- Over-Tightening Screws: Over-tightening screws can strip the wood or even crack it, especially in thinner materials commonly used in cabinet doors. Solution: Use the appropriate screw length and tighten them only until snug. Over-tightening is unnecessary and detrimental.

- Using Incorrect Screw Length: Using screws that are too short will result in weak joints, while screws that are too long can poke through the face of the cabinet door, ruining the aesthetic. Solution: Always use screws of the correct length specified by the Kreg Jig manufacturer for the material thickness.

- Ignoring Wood Grain Direction: Drilling across the wood grain can weaken the joint. Solution: Always align the pocket hole jig so that you are drilling along the wood grain, not against it. This ensures a stronger, more reliable joint.

Kreg Jig Model Comparison

The accuracy and ease of use of different Kreg Jig models significantly impact the final outcome. While all models share the basic principle, variations in design and features translate into differences in performance.

| Model | Accuracy | Ease of Use | Price |

|---|---|---|---|

| Kreg Jig R3 | High; self-aligning features ensure consistent pocket hole placement | High; intuitive design and clear instructions | High |

| Kreg Jig K4 Master System | High; multiple drill guides for various materials | Medium; more features require more learning | Medium-High |

| Kreg Jig K5 | Medium; simpler design, less sophisticated alignment features | High; very easy to learn and use | Medium |

| Kreg Jig Mini | Medium; suitable for smaller projects, but may lack precision for large doors | High; compact and portable | Low |

Tips for Precise and Strong Pocket Hole Joints

Achieving truly precise and strong pocket hole joints requires attention to detail beyond simply following instructions.

- Pre-Drilling Pilot Holes: Pre-drilling pilot holes helps prevent wood splitting, especially when working with hardwoods. This is crucial for maintaining the integrity of the joint and preventing costly mistakes.

- Using a Backer Board: A backer board prevents tear-out on the back of the workpiece when drilling pocket holes. This maintains a clean, professional finish, preventing unsightly damage to the back of the cabinet door.

- Clamping During Assembly: Clamp the assembled pieces firmly together while the screws are being tightened. This ensures even pressure and prevents misalignment.

- Wood Glue: Adding wood glue to the pocket holes before assembly significantly increases the strength and longevity of the joint. This simple addition greatly enhances the durability of the finished product.

Screw Selection and Drilling Techniques

The choice of screws and drilling techniques is paramount for achieving both durability and aesthetic appeal.

- Screw Material: Use high-quality screws designed specifically for pocket hole joinery. These screws are often hardened and feature a coarse thread for superior holding power. Avoid using cheap or inferior screws; their failure can compromise the entire project.

- Countersinking: Countersinking the screw heads slightly below the surface of the wood ensures a flush, smooth surface for a professional finish. This is a critical step for achieving a seamless, visually appealing result. Use a countersink bit specifically designed for the size of screw being used.

Advanced Techniques and Design Considerations for Cabinet Doors

Constructing cabinet doors that transcend the merely functional requires a sophisticated understanding of joinery, material selection, and finishing. While the Kreg Jig provides a robust foundation for pocket hole joinery, mastering advanced techniques unlocks the potential for truly exceptional craftsmanship. This section delves into the complexities of raised panel doors, multifaceted designs, and professional-grade finishing.

Raised Panel Cabinet Door Construction

Creating raised panels adds depth and visual interest to cabinet doors. This process necessitates precision and attention to detail, going beyond the simple face frame construction achievable with a Kreg Jig alone. The following steps Artikel the process:

- Panel Preparation: Cut the panel to the desired size, ensuring accuracy. A slight undersize is preferable to allow for expansion and contraction.

- Rail and Stile Assembly: Construct the frame (rails and stiles) using the Kreg Jig for pocket hole joinery. Ensure squareness and precise alignment. Glue and clamp the assembly firmly.

- Panel Routing (Optional): For a more refined look, use a router and appropriate bit to create a rabbet or dado on the inside edges of the frame to receive the raised panel.

- Panel Installation: Carefully insert the prepared panel into the frame, ensuring a snug fit. If using a rabbet or dado, glue may be necessary for added strength. Clamping is crucial for even pressure and to prevent warping.

- Finishing: Sand the assembled door thoroughly, paying close attention to the panel-to-frame transition. Apply finish according to your chosen method.

Complex Cabinet Door Design Incorporating Multiple Joinery Methods

This design utilizes a combination of techniques to create a visually striking and structurally sound cabinet door.

Imagine a door featuring a central raised panel, surrounded by a frame constructed from contrasting wood species. The frame itself would incorporate both Kreg Jig pocket holes for the stile-to-rail joinery and traditional mortise and tenon joints at the corners for enhanced strength and visual appeal. The raised panel would be secured using a combination of glue and small brads or finishing nails, concealed within the rabbet. The contrasting wood species would enhance the visual impact, potentially using a darker wood for the frame and a lighter wood for the panel. Materials could include hardwoods such as cherry, walnut, or maple, selected for their durability and aesthetic qualities.

Cabinet Door Finishing Techniques

Proper finishing is critical for durability and aesthetic appeal. The following steps provide a framework for a professional finish:

- Sanding: Begin with coarser grit sandpaper (e.g., 80-grit) to remove imperfections, progressively moving to finer grits (e.g., 120, 180, 220) for a smooth surface. Pay special attention to edges and corners.

- Cleaning: Thoroughly remove sanding dust using a tack cloth or compressed air. Any remaining dust will negatively impact the finish.

- Stain Application (Optional): Apply stain according to the manufacturer’s instructions, using a brush, rag, or spray gun. Allow ample drying time before proceeding.

- Sealer Application: Apply a wood sealer to protect the wood and ensure even paint adhesion (if painting). Allow for sufficient drying time.

- Paint Application (Optional): Apply paint in thin, even coats, allowing each coat to dry completely before applying the next. Multiple thin coats are preferable to one thick coat.

- Topcoat (Optional): Apply a clear topcoat (e.g., polyurethane, lacquer) to protect the finish and enhance its durability. Allow ample drying time between coats.

Necessary materials include sandpaper (various grits), tack cloth, stain (optional), wood sealer, paint (optional), brushes or spray gun, topcoat (optional), and rags or lint-free cloths.